brinell hardness test experiment|brinell hardness testing charts : distributor Brinell Hardness Test. Brinell hardness test is most commonly used to test materials that have a structure that is too rough or too coarse to be tested using other test methods, e.g., castings and forgings. Resultado da Para deixar itens no chão, equipe-os e pressione "Q", no teclado, ou o botão de soltá-los no controle, ou ainda clicando na comida, em seu inventário, e arrastando-a para fora. 7. .

{plog:ftitle_list}

Resultado da 16 de nov. de 2023 · Clique agora para baixar e ouvir grátis NADSON O FERINHA 2023 | PIOR PARTE postado por beckacds2023 em 16/11/23 às 19:36, e que já está com 193 downloads e 3564 plays! . NADSON O FERINHA 2023 | PIOR PARTE . Adicionar à fila. beckacds2023 + Seguir. .

In this article, we have seen the Brinell hardness test and its two different methods – Standard and Non-Standard Brinell hardness tests. Also, discussed its advantages, disadvantages or limitations, and applications.

Brinell Hardness Test. Brinell hardness test is most commonly used to test materials that have a structure that is too rough or too coarse to be tested using other test methods, e.g., castings and forgings.

The Brinell hardness test is an optical testing method for samples with coarse or inhomogeneous grain structure. This is the best test method for .brinell hardness test The Brinell test for this experiment uses steel ball with different diameters which is pressed into a specimen by a different load that is maintained for 15 to 30 seconds. Brinell Hardness Test. Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition of the.

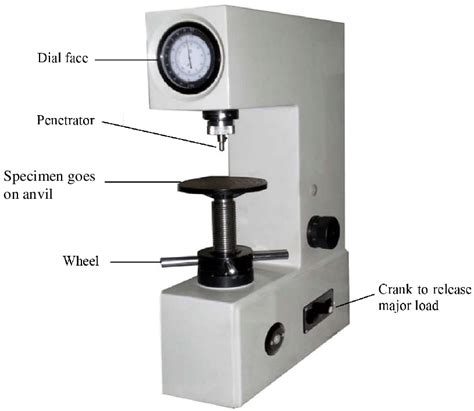

The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested .the measure of the hardness of the material. BRINELL HARDNESS TEST The Brinell test for this experiment uses steel ball with different diameters which is pressed into a specimen by a different load that is maintained for 15 to 30 seconds. The Brinell hardness number (BHN) is calculated by: [ √ ] Where: P is the test load [kg] About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .1. Rockwell hardness test (scales A, B & C) methods : IS:1586-1988 Viva Questions: 1. What is Hardness? 2. What is the significance of minor load in Rockwell method of hardness testing 3. What are the advantages and limitations of Rockwell method of hardness testing 4. Where are Rockwell hardness test and Brinell hard test employed 5.

rockwell hardness tester procedure pdf

Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition .Brinell Hardness Test. Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter hardened steel ball as an indenter with a 3,000 kgf (29.42 .Apparatus: Brinell hardness tester Weights Mild steel sample Microscope (scale and graduated) Steel ball (indenter) THEORY: Hardness is the property of a material by virtue of its ability to resist indentation and scratching by harder bodies. . EXPERIMENT 3: HARDNESS TEST OBJECTIVE The objective of this experiment is to determine the hardness .

hardness tester lab report pdf

Hardness Testing Lab (Brinell and Rockwell) . To record the results during the experiment of each test we conduct for later calculations. Objectives: • • • Write a report on Hardness testing using two methods Rockwell and Brinell and describe them using different headings including procedure, Apparatus, results and come up with a . In the experiment al work that has been carried out, in the case of the Vickers hard ness testing. . of the Brinell hardness testing it corresponded to 0.26 HB. Considering that the hardness .

The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .Experiment 1 lab 244; LAB 4 Report; Engr 244 lab 6 - engr 244 lab 6 academic year 2016/2017; Lab 3 ENGR 244 - engr 244 lab 3. for academic year 2016/2017; . , Brinell Hardness test will be used to determine the level of hardness applied from a 10 mm steel ball indenter onto a steel and aluminum disc under different applied force.

In metallurgy: Testing mechanical properties .oldest of such tests, the Brinell hardness test, uses a 10-millimetre-diameter ball and a 3,000-kilogram load. Brinell hardness values correlate well with UTS.BRINELL HARDNESS TEST I. AIM: To determine the Brinell hardness of the given test specimen. II. APPARATUS: Brinell hardness machine, test specimen. . Repeat the experiment at other positions of the test piece. 9. Calculate the value of HB. V. OBSERVATIONS: Test Piece Material = Diameter of Ball ³D ´ = Load .ME 212 LABORATORY EXPERIMENT #3 HARDNESS TESTING AND AGE HARDENING 1. OBJECTIVE: . BRINELL HARDNESS TEST: This test consists of applying a constant load, usually between 500 and 3000 kgf for a specified time (10 to 30 s) using a 5- or 10-mm diameter hardened steel or tungsten

Objective The objective of the experiment is to understand and use the Brinell hardness test to measure the resistance of different metals to indentations under a specific load. The two metals that will be tested are Aluminum and Steel. Introduction Hardness can be defined in several ways as there are different tests for them now. According to Brinell, hardness can be defined as .Introduction Calculation of Brinell hardness testing is a popular technique for determining a material’s hardness, especially for metals and alloys. It evaluates a material’s resistance to irreversible deformation under particular load and . Introduction, Test Procedure, Calculation Formula, Advantages

This document describes an experiment using the Brinell hardness test method. The objectives are to familiarize students with the Brinell test and expose them to another hardness testing method. The experiment involves . The results of experimental studies on determining the Brinell hardness values of high-strength steels are presented. The experimental data show that the existing regulatory documents do not fully provide reliable information about the properties of materials. . Brinell hardness test. Part 2. Verification and calibration of testing machines .The main objective of this experiment is to introduce two important basic mechanical property tests; hardness (using Rockwell testing) and impact (using Charpy testing). Chauvenet’s Criterion will be applied to identify . Rockwell hardness differs from Brinell hardness testing in that the indentation size is measured in Brinell

Water Vapor Permeability Tester TV shopping

An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm.This is applied under a load P of 500–3000 kg applied for 10–30 s.The diameter of the circular indentation d is measured in millimetres. The hardness number, (HB) is calculated using the following equation:

The Brinell method has the following advantages: The Brinell method can be used for testing non-homogeneous materials (e.g. castings), because the large ball comes into contact with many crystals (different metallographic constituents of the material), thereby forming a . We performed this experiment in LORDS Institute of Engineering & Technology where we find good facilities and lab equipment.-----.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

Experiment # Brinell Hardness Test Dorian Kamte (40300034) Section AM-X Submitted on May 19, 2024 Lab Group Members: Khalid Syed Sourena Nezamivand Chegini. Objective The objective of this laboratory experiment is to determine the hardness of several metallic samples.

General Information about the Brinell Hardness Test. The Brinell hardness test involves pressing a hard ball indenter, usually made of tungsten carbide, into the material’s surface with a specified force. The diameter of the ball is typically 10 mm, but smaller diameters such as 2.5 mm can also be used for specific applications.Experiment No.: 02 Title: Brinell hardness test. Aim: To determine the hardness of the given specimen using Brinell hardness test. Materials and equipments required: 1. Brinell hardness Tester (Fig.2) Brinell Microscope.2. 2. Specimen 3. Ball indenter (Dia = 5 mm.) Precautions: 1. Thickness of the specimen should not be less than 8 times the .

This experiment will focus on the Brinell Hardness Test and its application. The Brinell test was one of the earliest widely acknowledged tests for hardness measurement. To compute the Brinell hardness number, a steel ball with a diameter of 10 mm is used as an indenter to make an impression on the test piece.

hardness test lab report pdf

Pornô mais procurados do Dia. viniendose. Studio 99 Palmas To - Assistir os melhores videos porno grátis sobre Studio 99 Palmas To. Site adulto publicando milhares de pornografia online.

brinell hardness test experiment|brinell hardness testing charts